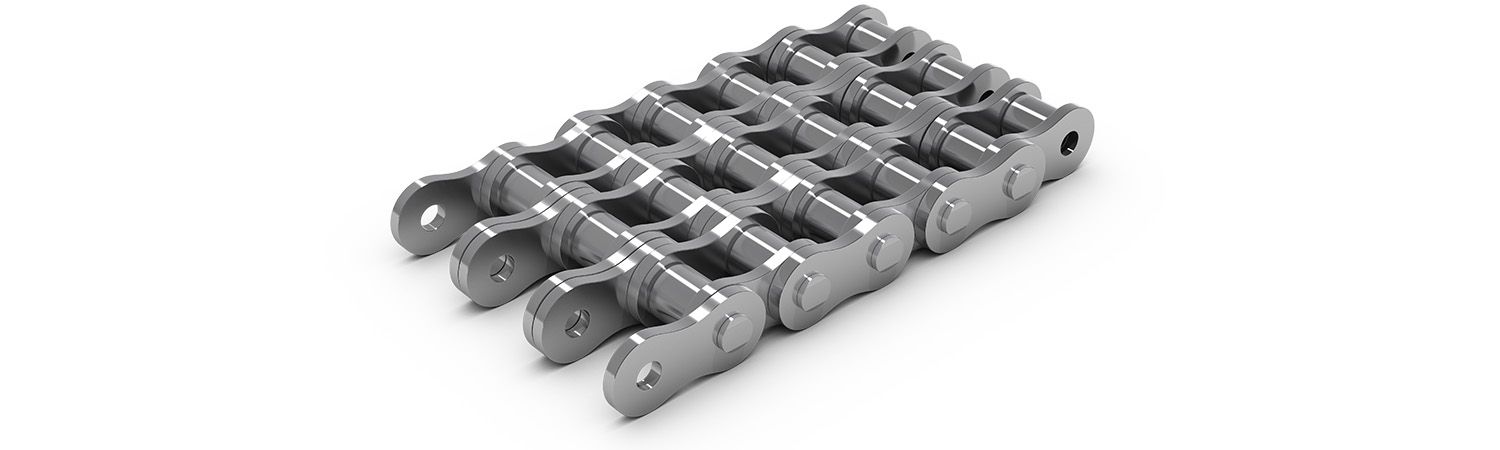

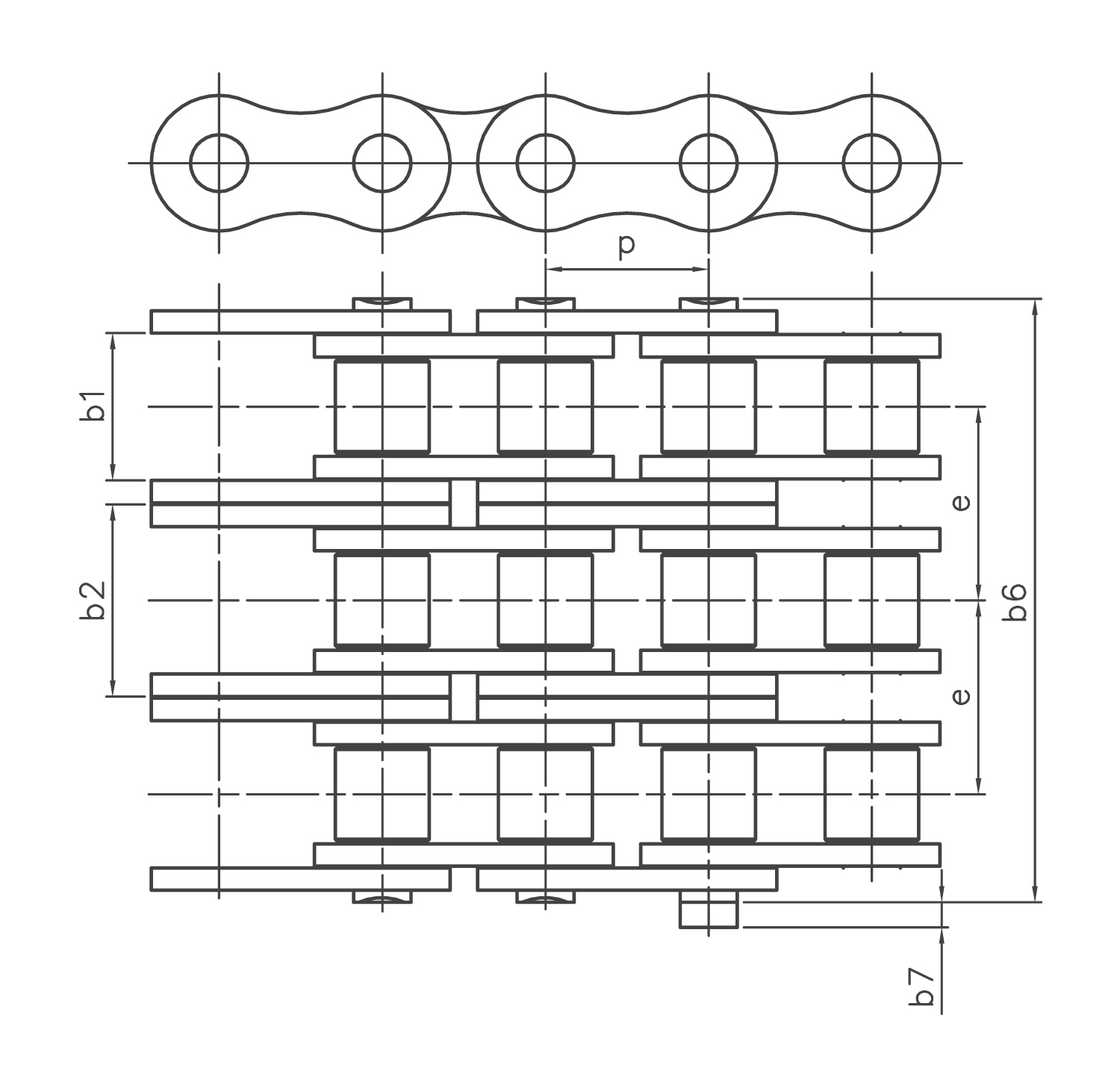

ROLLER CHAINS type B

triple-strand

In terms of the design, we can distinguish simplex, duplex and triplex chains, while in terms of the size, type A and B (size differences are shown in the table).

In these chains, the rollers (extruded and calibrated) seated on the pins increase their durability and lifetime, and reduce gear wheel wear. Thanks to our 30 years of experience, strict control and using only high quality steel for chain production, we can ensure maintenance-free operation of the customer’s equipment, while reducing the machine park maintenance costs.

They are most often used in areas where high requirements are in place: the automotive sector, machine and equipment construction, and the packaging, printing, food and agriculture industries.

Type A roller chains differ from type B in terms of their size, due to their thicker plates and bigger rollers, which greatly improve their durability.

Thanks to our 30 years of experience,

strict control and using only high quality steel for chain production, we can ensure maintenance-free operation of the customer’s equipment, while reducing the machine park maintenance costs.

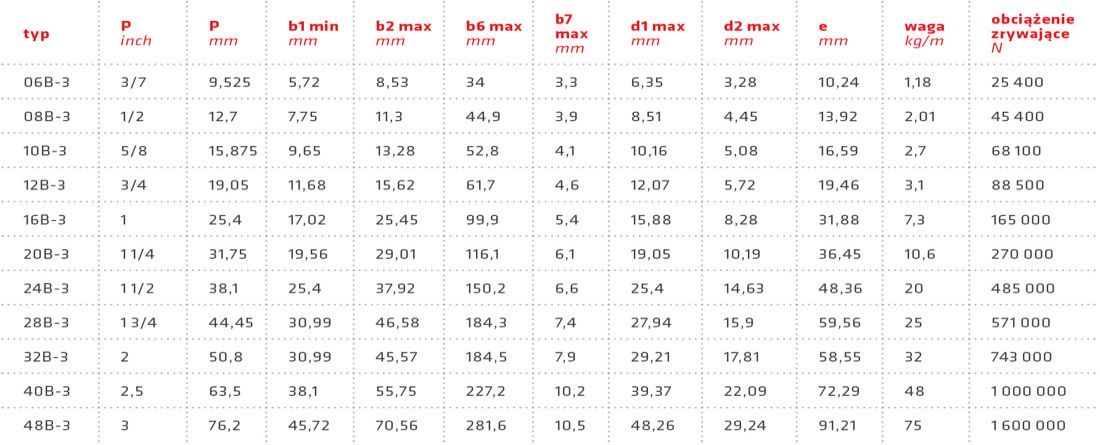

Technical Specifications

Interested in our Products?

Leave us your e-mail address and phone number and we will contact you.

Examples of applications

Packaging Industry

Machine Industry

Automotive Industry